-

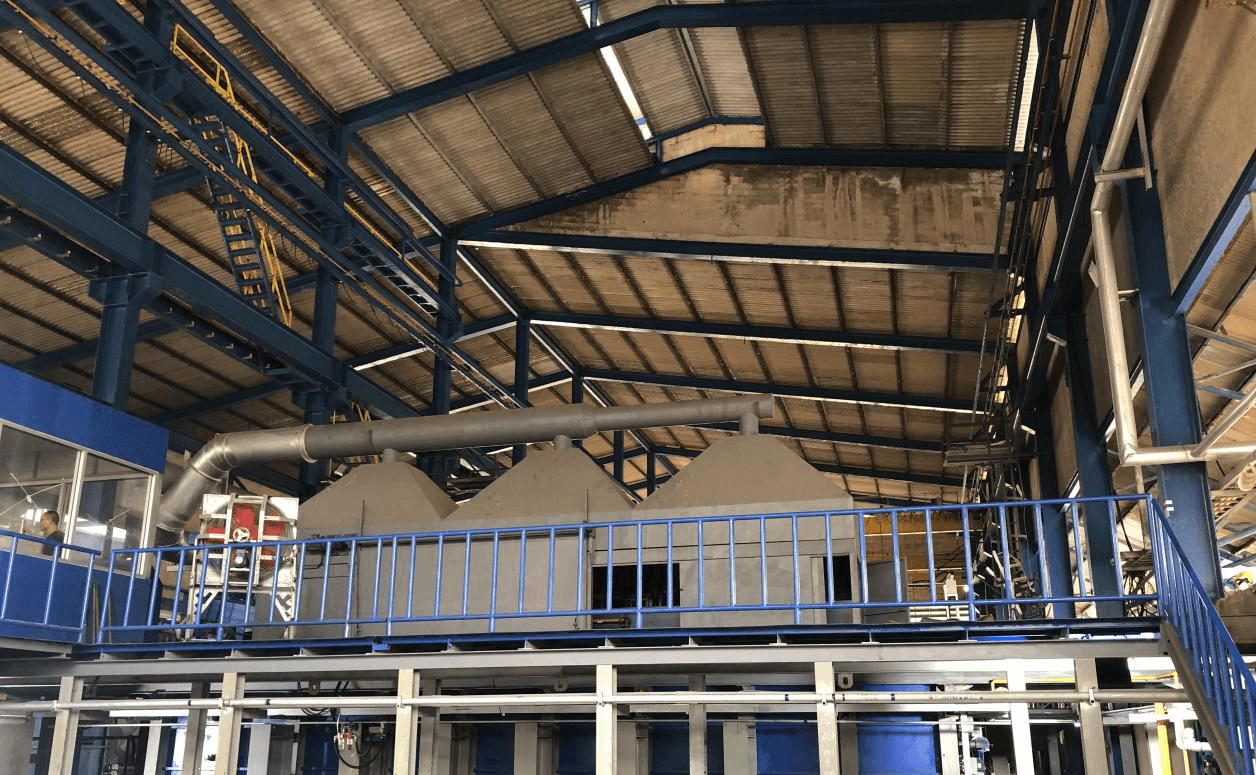

This production line is specially designed for hot-dip galvanizing of steel pipes. It can produce both small pipes and large pipes on one production line. The product range is from 1/2"~8". Steel pipe can be hot-dipped in zinc kettle automatically. Steam injection is used inside steel pipe and compressed air injection is used outside.

PRODUCTION RANGE

|

Key Figures |

Branches/ |

Thickness rang(mm) |

Capacity every 8 hours |

Pressing method |

Lifting method |

Inside blow method |

Type of Air |

|

Φ21-Φ32 |

4 |

1.5-3.25 |

90T |

Pneumatic |

Pneumatic |

Fixed inside |

Steam |

|

Φ42-Φ76 |

2 |

2-4.0 |

105T |

Pneumatic |

Pneumatic |

Guide shaft inside blow |

Steam/ |

|

Φ89-Φ114 |

2 |

3.0-5.0 |

120T |

Pneumatic/ |

Pneumatic |

Guide shaft inside blow |

Steam/ |

|

Φ140-Φ219 |

1 |

4.0-6.5 |

140T |

Pneumatic/ |

Pneumatic |

Guide shaft inside blow |

Steam/ |

SUPPLY RANGE

- Degreasing tank

- Pickling tank

- Washing tank

- Fluxing tank

- Iron removal device

- Pre-treatment room

- Drying table

- Heating furnace

- Galvanizing Unit

- Zinc kettle

- Drag-out unit

- Outside-blowing machine

- Pulling-up device

- Inside-blowing machine

- Cooling tank

- Parallel motion device

- Steam Storage irrigation

- Boiler

- Reheating furnace

- Electrical section

- On-line painter

- Acid mist absorber

- Dust collector

- Auto packing line