-

Project Name: Hot-dipped Galvanizing Line

Project Time: 2019

Pipe Size: 2"-6"

Galvanizing Standard: BS1378, ASTM A53

Location: Rayong, Thailand -

Thailand Galvanizing line is a renovation project. WRD engineer team has to make new design form the drying table till the cooling tank section. Based on the 20 more years old galvanizing lines, Our chief designer repeatedly optimizes the design plan, in order to save the budget for customers and improve production efficiency, he spent a lot of efforts.

Hot Dipped GI Line - Thailand

The reformed galvanizing line mainly consists of the following parts:

-

Drying table

Heating furnace

Zinc pot

Galvanizing machine

Inside and outside blowing

Cooling tank

Boiler

Dust collectors

Superheat furnace

Several highlights for this project:

1 Drying Table

-

The design of drying table utilizes the waste heat of galvanizing heating furnace, which is environmentally friendly, energy-saving and efficient.

-

Drying Table-1

-

Drying Table-2

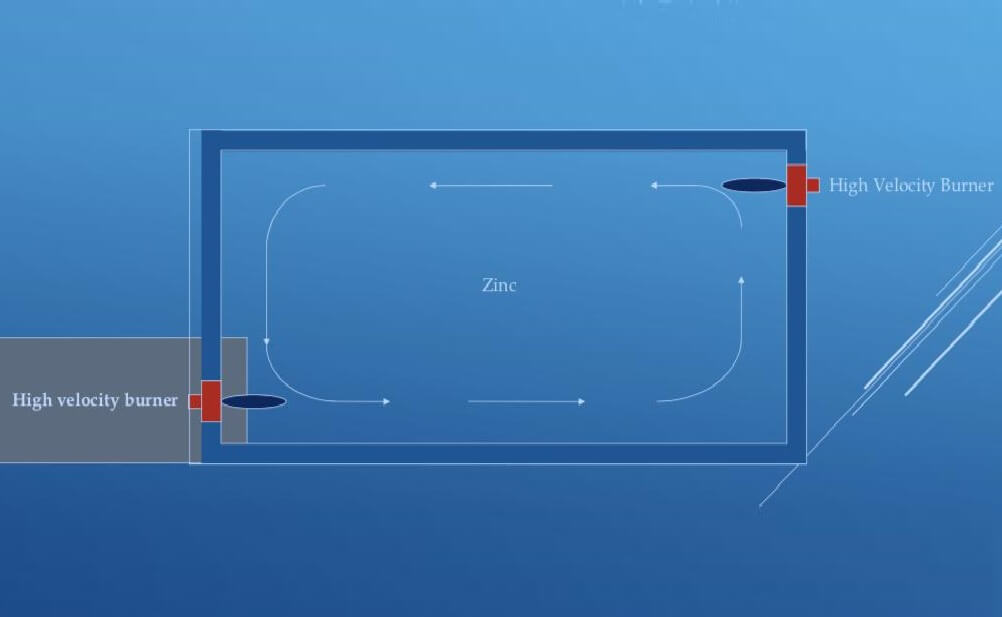

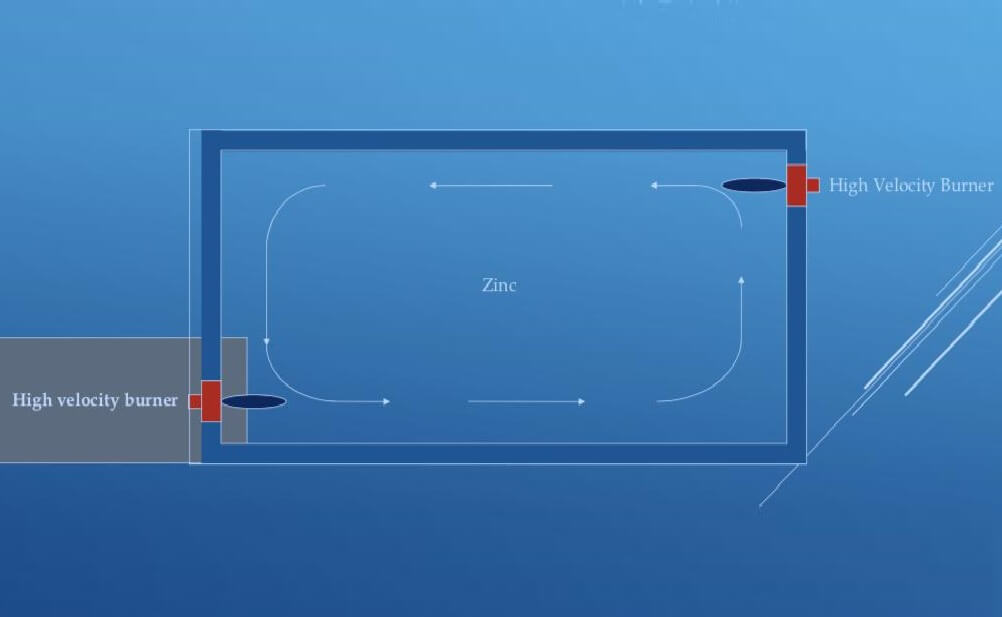

2 Pulse Fire High velocity combustion system

Simple design

High precision control for temperature

High heat transfer efficiency and low fuel consumption

Temperature uniformity

Longer kettle service time

-

Buners design

-

Furnace outlook

3 Dust collectors

-

Two dust collectors design: one for collecting the zinc power from kettle cover and the other for collecting the zinc power from the inside blowing.

-

Dust collector-1

-

Dust collector-2

-

Some pictures taken on site:

Hot Dipped Galvanized Steel Pipe

Cases

Hot Products

Hot news